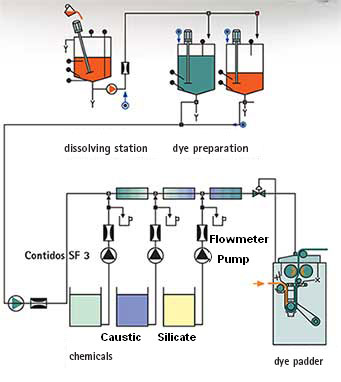

Automation solution for Dosing System for Kusters Dye Padder :

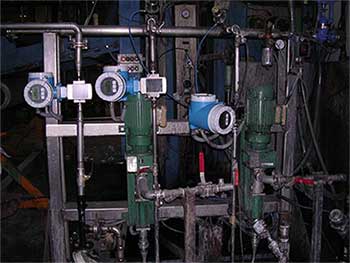

Dosing System (First in India) for Kusters Dye Padder comprising of Allen Bradley PLC system, Touchscreen MMI and Instrumentation including Endress + Houser Flowmeters,

Metering Pumps, Sensors & Actuators.

The retrofit package of the automation consisted of Allen Bradley PLC and 10” Touch Screen Graphic User Interface

The Centralized Hardware panel for combined operation of various sections that constitute a complete Dosing needed for an accurate or precise dosing of silicate and Caustic in Dye Liquor.

|

|

|

Operational Simplicity :

As in conventional case, we have SERA PUMP or reciprocating pump for mixing of dye liquor colour and silicate with the ratio set. The dosing so is of open loop type with no correction with respect to the actual ratios.

Where as in this the actual readings of the silicate in accordance to dye liquor are always compared with set silicate (ml/l of dye liquor). So the ratio of silicate to dye liquor accuracy is far improved and under observation. This is one of the important aspect of this system.

In addition to these following are added advantages :

- Dosing of each individual chemicals according to recipe quantity in ml/l of dye liquor.

- Metering of liquor pick-up.

- Consumption record.

- Small losses of dye liquor and short rinsing process in case of colour changes.

- Dosing capacity according to recipe and production capacity.

- PLC control with operator terminal.

- Link to process control system.

- Dissolving station and preparation station available.

Cost Effective :

All these advantages are provided at very reasonable cost comparative to imported machinery manufacturers.

Customer’s Feedback :

The Arvind Mills Ltd. Ahmedabad. Indigenous automation package successfully commissioned for one of the Kusters make Dyeing Padder of M/s. Arvind Products Ltd, Ahmedabad, Advantages with new system :

|

|

|

|